PRECISION PARTS AND ASSEMBLIES WITH NO TOLERANCES

Absolute precision, on-time delivery and just-in-time deliveries are part of our everyday work at OMS®:

From design to production to high-precision measurement technology and documentation, we ensure that our customers’ expectations for our “components” are not only fulfilled, but exceeded in most cases. Upon request, we include test reports and certificates with our deliveries.

Outstanding reliability and very short lead times inspire us each day in all we do, as well as our customers.

PROCESSING WITHOUT TOLERANCES

We use our modern machine fleet for turning, milling, grinding, and sawing: machining from solid material as a manufacturing process for metal components can be used for all workpieces, and in particular to fulfill complex requirements.

Our machine fleet is designed to meet any requirement:

turning up to D=600 mm / L=1500 mm

milling up to 1200 mm edge length

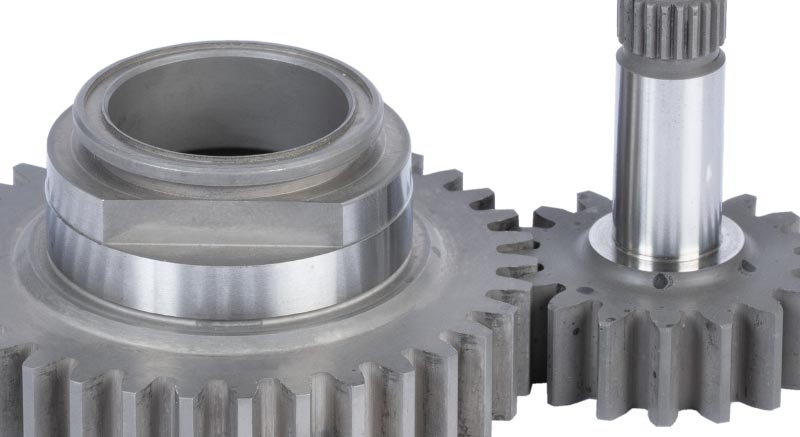

TECHNOLOGY WITH THE HIGHEST PRECISION.

Everything from a single source

Tooth geometry is key to ensuring smooth running and eliminating backlash. Developed in accordance with the GLEASON process, the geometry is implemented in high-performing gear technology thanks to highly optimized calculation, manufacturing, grinding, and testing processes.

Minimum parts from module 0.7 mm

Maximum parts to module 8.0 mm

SURFACES IN THEIR MOST BEAUTIFUL FORM.

Ready-to-use surface finishing.

We have a large number of technical processes for finishing component surfaces that can be used to improve component surface properties. This allows us to improve both the functional properties of the component (such as by providing higher wear protection, corrosion protection, preventing contamination) and the decorative properties (such as through color changes, gloss level, etc.). Our portfolio ranges from pre-treatments such as staining, blasting, or impregnating, hot-dip galvanizing, and nickel-plating, to powder coating, cathodic dip coating, laser marking, and even hard coatings (physical vapor deposition etc.).

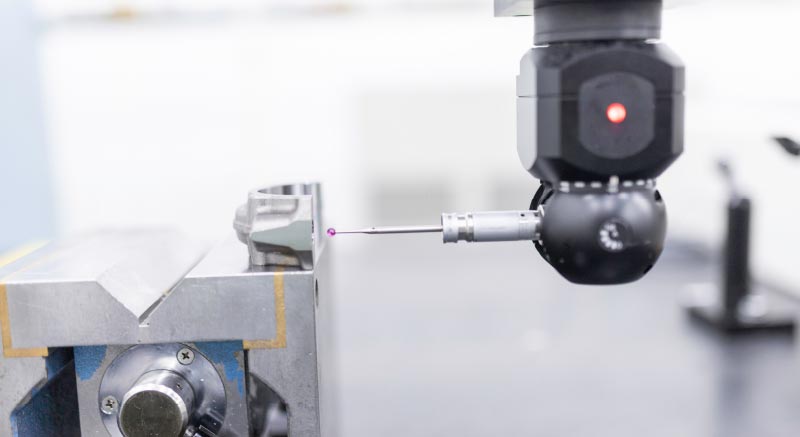

TRUST IS GOOD.

Measuring is better.

Our measurement processes are comprehensive, and carried out with the latest technologies and systems:

Contour measurement, form testers, hardness testing, surface measurement, coordinate measurement, and gear measurement.

ASSEMBLY FITTING

From simple to complex.

We make outsourcing a reality: we relieve our customers’ workload and handle part purchasing and component assembly.

The process chain for precision part manufacturing finishes with the mounting of complete assemblies. We use state-of-the-art assembly technologies (riveting, pressing, bonding, etc.), and press-fitting standard parts such as nuts, bushings, bolts, sealing work, insulation and soundproofing.

Pre-assembly of electrical components

Material management for purchased parts

SHIPPING & LOGISTICS

The right place at the right time – we move us.

Consignment warehouse

Concluding framework contracts allows us to pre-manufacture components inexpensively. We then store these until they are called off by the customer. This minimizes storage costs and logistical expenses for our customers.

Picking

Our team has many years of experience in customized picking. Your products will be collected and readied for delivery in the desired form quickly, efficiently, and reliably, then packaged to prepare them for transport.

Delivery

We deliver by freight carrier, courier, or OMS®‘s own vehicle fleet, just in time and as agreed. Our logistics experts ensure that your delivery arrives at the right time, exactly where it is needed.

Reusable packaging

Whenever it makes sense to do so from an ecological standpoint, we use reusable packaging specifically tailored to our customers’ products.